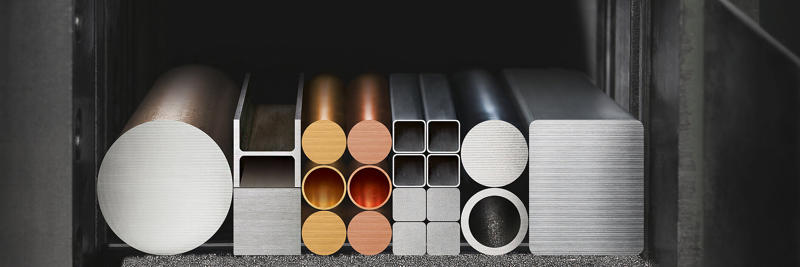

Bimetal band saw blades

Optimal product portfolio for standard and special applications

Band saw blades with M42 cutting edge

The backing material of the band saw blade is made of alloy steel, which offers excellent properties for long-term operation.

The proven M42 high-speed steel on the tooth tips offers high wear resistance in conventional applications.

PRIMAR M42

The versatile option in Level-1 for small and medium-sized workpieces

MARATHON M42

The all-rounder for small and large cross sections

MARATHON SW M42

Special geometry for cutting materials with internal stress

PROFLEX M42

The perfect band saw blade for profiles

PROFLEX SW M42

Special geometry for cutting profiles with internal stress

SKALAR M42

High-performance band saw blade

SELEKTA GS M42

High performance with excellent cutting surface

M42 band saw blades with coating

Optimum properties are ensured by an alloy steel backing material with high-speed steel tooth tips.

By coating, the highest possible performance and service life can be achieved.

PROFLEX PREMIUM M42

Coated band saw blade for profiles

PROFLEX PREMIUM SW M42

Coated band saw blade for profiles with internal stress

SKALAR PREMIUM M42

High performance and extremely long service life

SELEKTA GS PREMIUM M42

High performance, excellent cutting surface and long service life

Band saw blades with X3000 cutting edge

The backing material of the saw blade is made of alloy steel, which offers excellent properties for long-term operation.

The modified X3000 high-speed steel on the tooth tips (exclusive to WIKUS) offers high durability and toughness.

High cutting edge stability when cutting difficult to machine materials and special alloys.

MARATHON X3000

The special band saw blade for high-strength and difficult-to-cut materials

SKALAR X3000

Powerful band saw blade for materials with high tensile strength

SELEKTA GS X3000

Powerful band saw blade with excellent cutting surface for durable materials

Band saw blades for wood cutting

The backing material of the saw blade is made of alloy steel, which offers excellent properties for long-term operation.

High speed steel (HSS) at the tooth tips offers high durability and toughness.

You might also be interested in

Tooth pitch selection

The decisive factors for the choice of tooth pitch are the contact length of the blade in the workpiece (the longest uninterrupted part of the cut) and, in the case of profiles, the wall thickness. Choose the toothing suitable for your material.

Practical tips

With more than 60 years of experience in the industrial cutting industry, we share best practices to help you achieve better results: from factors affecting band saw blade life, via cost-saving opportunities, to identifying the causes of potential failures.

Contact

No matter whether your operation is located in London, Manchester or Glasgow, we have an expert technician on hand who is always ready to help you. Contact us and together we will find a solution.