Parameters for selecting a band saw blade

There are various factors to consider when choosing the right band saw blade:

- type of band saw machine

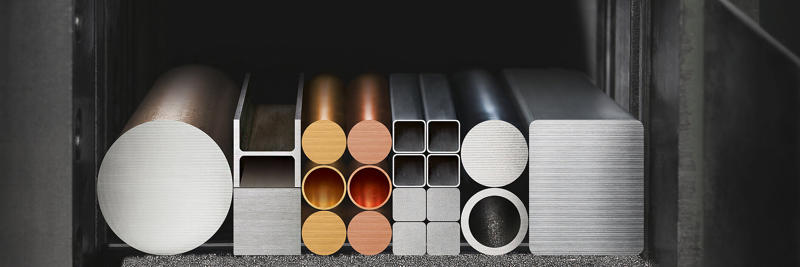

- quality of the material to be cut

- dimension and shape of the workpiece

- single, layered or bundle cutting

- individual requirements

Each machine has a specified blade length, which is indicated in the technical documentation of the machine or on the label. If you are not sure, you may find our tables for world known machines.

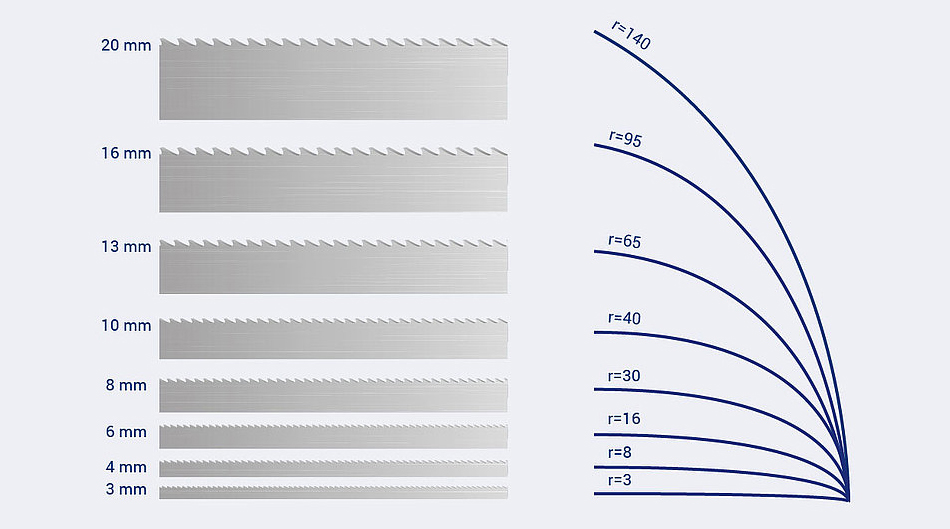

In principle, the greater the height of the band saw blade, the greater its stability in the cut.

- Horizontal machines

More standardized dimensions. Further information can be found in the manual or on the saw's label. - Vertical machines

It often offers different variations of usable band saw blade heights. Possible adaptation to the material being cut. - Contour cutting

As a rule for vertical machines, where the smallest possible radius to be cut is determined by the height of the blade.

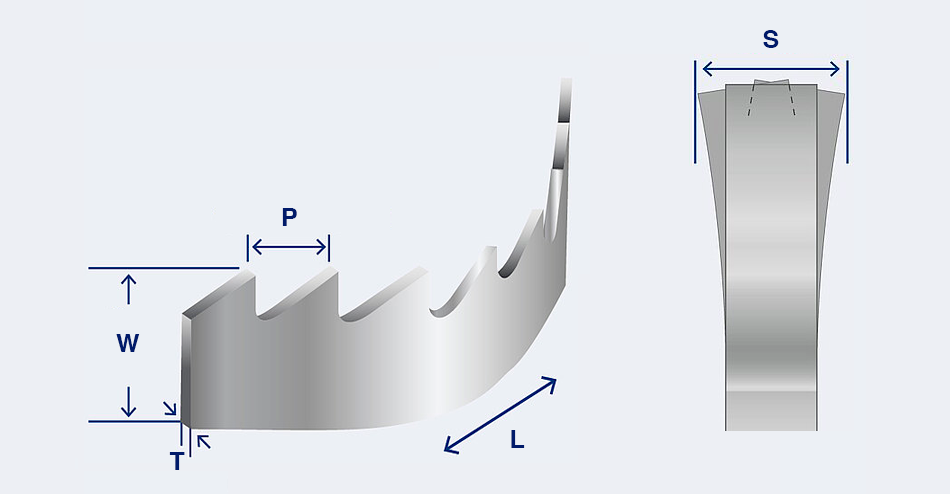

The thickness of the band saw blade basically ensures stability in the cut, but affects the resistance to twisting.

- Depending on the design of the band saw machine, the thickness of the blade at the same height may vary.

(54 x 1,60 / 54 x 1,30 a 54 x 1,10 mm) - The thickness of the band saw blade directly influences the flatness of the cut.

The decisive factors for the choice of tooth pitch are the contact length of the band saw blade in the workpiece (the longest uninterrupted part of the cut) and the material to be cut. WIKUS offers products with constant and variable tooth pitch.

Tooth pitch selection

| Number of teeth per inch (tpi) | Diameter of solid material (mm) | Profile wall thickness (mm) |

|---|---|---|

| 18 | - | 0-2 |

| 14 | - | 1-4 |

| 10-14 | 0-20 | 3-5 |

| 8-12 | 10-30 | 4-6 |

| 6-10 | 20-50 | 5-8 |

| 5-8 | 30-60 | 8-10 |

| 4-6 | 50-90 | 12-16 |

| 3-4 | 80-150 | 16-22 |

| 2-3 | 120-300 | 20-35 |

| 1,4-2 | 250-600 | 30-85 |

| 1,0-1,4 | 400-1000 | 40-85 |

| 0,75-1,25 | 600-2000 | - |

| 0,7-1,0 | 1000-3000 | - |

To make it easier for you to navigate, the table has been simplified. However, if you are interested in a detailed and accurate view, please continue to tooth pitch selection table.

The choice of tooth geometry depends on the material to be cut.

WIKUS offers the following tooth shapes:

- S = standard

- K = positive

- K = extremely positive

- P = profile

- T = trapezoid

- TSN = trapezoid with negative rake angle

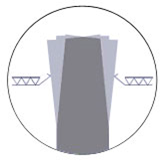

The precise offset of the teeth to the sides allows the belt to cut freely.

Possible options include:

- Standard setting (SD)

- Staggered setting (SFN)

- Group setting (GS)

- Wavy setting (WS)

- Wide setting (SW / NE)

The machinability of the material is a key factor in selecting the appropriate cutting edge quality.

The WIKUS product portfolio consists of four main groups of cutting materials:

- HSS (bimetal)

Hardness: approx. 940-1000 HV

Resistance: approx. 600 °C

Materials: up to 45-50 HRC - Carbide

Hardness: approx. 1600-3800 HV

Resistance: approx. 800 °C

Materials: up to 62-65 HRC - Diamond

Hardness: approx. 9000 HV - Cubic boron nitride (CBN)

PD

The significantly positive tooth rake angle of the special PD design brings aggressive cutting characteristics to the band saw blade. It is particularly advantageous when cutting stainless steels and exotic alloys. In general, it is advantageous when cutting solid materials of medium and larger dimensions.

PW

Wikus development engineers developed this wave-shaped band saw blade for cutting stainless steels and exotic alloys. When cutting these materials, the PW design delivers exceptional cutting performance as well as high durability. These advantages are particularly evident in large material sizes.

- SKALAR M42, SKALAR PREMIUM M42, SKALAR X3000

- SELEKTA GS M42, SELEKTA GS PREMIUM M42, SELEKTA GS X3000

- DUROSET, DUROSET PREMIUM

- FUTURA, FUTURA PREMIUM

- FUTURA VA, FUTURA PREMIUM VA

PE

It has ground (egalised) tooth sides, which ensures that none of the teeth protrude within the tolerance of the other teeth of the band saw blade. It is designed for cutting aluminium in particular, when exceptional surface quality of the material to be cut is required.

Technical principles

Find out the difference between tooth pitch and tooth setting. What geometries we offer and what they are suitable for. This information is the basis for a good orientation of the band saw blade segment.

Tooth pitch selection

The decisive factors for the choice of tooth pitch are the contact length of the blade in the workpiece (the longest uninterrupted part of the cut) and, in the case of profiles, the wall thickness. Choose the toothing suitable for your material.