We advise you how to cut more efficiently

With more than 60 years of experience in the industrial cutting industry, we share best practices to help you achieve better results: from factors affecting band saw blade life, via cost-saving opportunities, to identifying the causes of potential failures.

Blade life influences

Ensuring the right operating conditions is one of the prerequisites for achieving perfect results. Optimally, the operator should check the condition of the machine and its settings step by step at each tool change.

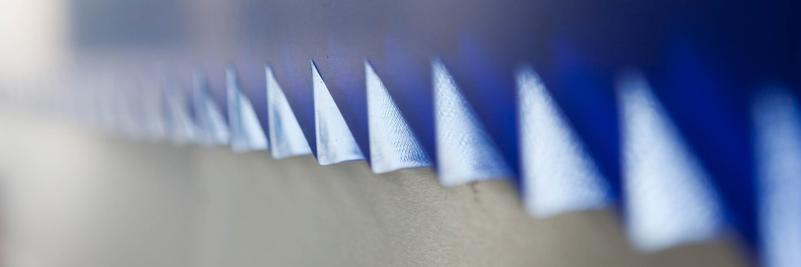

Breaking-in information

In order to achieve good performance and a long service life, the band saw blade must first be run in and the cutting edges slightly rounded. This simple but important step will ensure the reliability and efficiency of the tool.

Machine operators

Take advantage of all the ways to achieve a longer service life for your band saw blades. This brings huge savings potential, not only in simple cost per cut, but also in administrative and operational savings through less frequent replacements.

Causes of failures

Everybody encounters this at some point. The band saw blade doesn't cut or cuts badly. The type and extent of the damage can tell you a lot about the cause of the fault. The blade is just one of four possible places to look.