Technical advice

We have been living this craft for the third generation. Chips are already part of our DNA and we are happy to share our years of experience with you. If you don't find the answer on our website, don't hesitate to contact us - we are here for you.

When choosing a band saw blade, we focus on your individual requirements:

- lifetime

- cutting time

- economy of operation

- surface quality / cutting geometry

Besides individual objectives, general conditions also influence selection:

- type of band saw machine

- quality of the material to be cut

- dimension and shape of the workpiece

- single, layered or bundle cutting

There is an ideal solution for everyone in our portfolio:

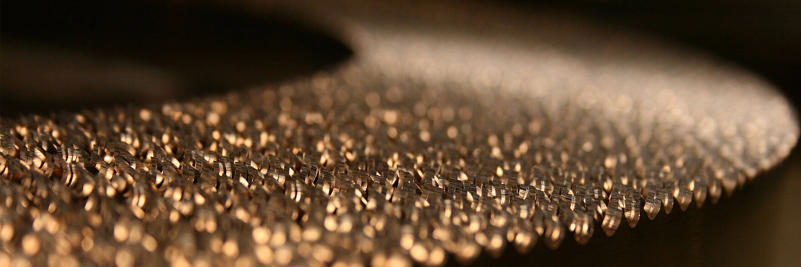

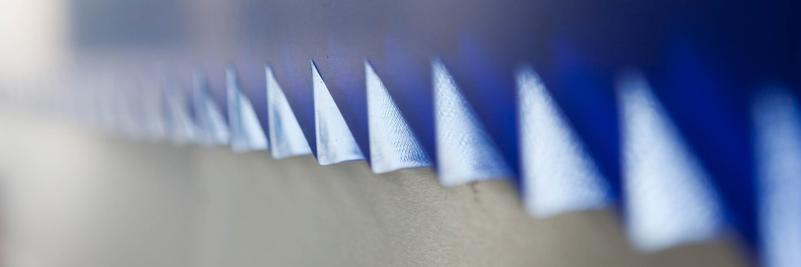

- customised tooth shapes

- various pitches

- precise tooth setting

- individual blade lengths and heights

- special geometries PE and PW

Technical principles

Find out the difference between tooth pitch and tooth setting. What geometries we offer and what they are suitable for. This information is the basis for a good orientation of the band saw blade segment.

Band saw blade selection

In order to design the right solution, we will need some basic information from you regarding the machine and the material to be cut. The machine will tell us the dimensions of the saw blade and the material will determine the direction to take.

Practical tips

With more than 60 years of experience in the industrial cutting industry, we share best practices to help you achieve better results: from factors affecting band saw blade life, via cost-saving opportunities, to identifying the causes of potential failures.

Breaking-in information

In order to achieve good performance and a long service life, the band saw blade must first be run in and the cutting edges slightly rounded. This simple but important step will ensure the reliability and efficiency of the tool.