Running-in information

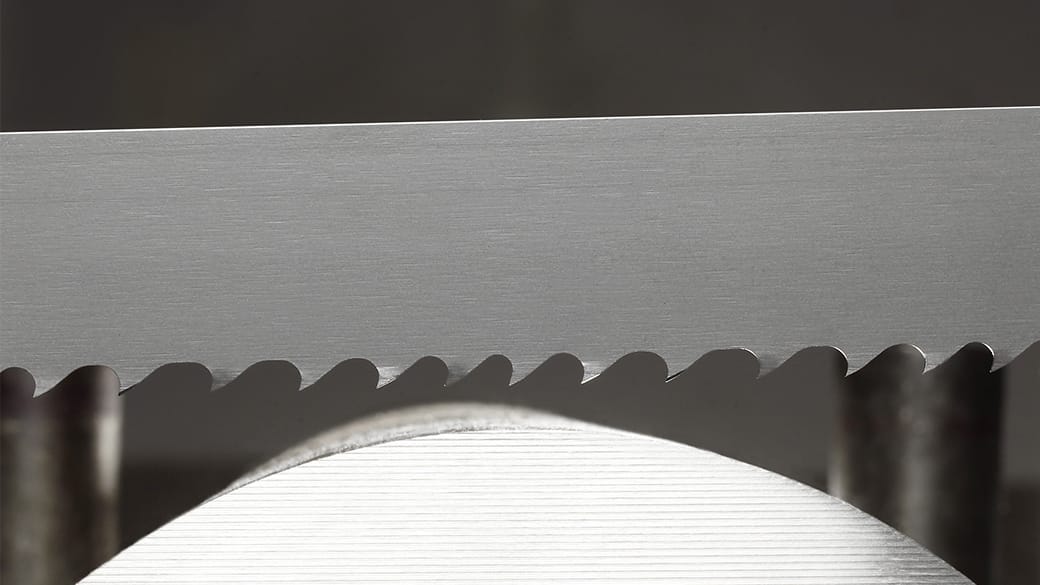

In order to achieve good performance and a long service life, the band saw blade must first be run in and the cutting edges slightly rounded. This simple but important step will ensure the reliability and efficiency of the tool. Otherwise, there is a risk of a significant reduction in the service life, accuracy or performance of the band saw blade.

To achieve ideal results, it is crucial to ensure the lowest possible vibration during the break-in process. If the tool is noisy, it is recommended to further adjust the parameters until there is a silencing in the cut.

- Find out the recommended values for blade speed (m/min) and cutting feed (mm/min) according to the shape and quality of the material to be cut.

Parameter settings

Bimetal band saw blades

- 100% cutting speed (m/min) and 50% feed rate (mm/min) compared to recommended values

- for smaller materials for 15 minutes

- for large materials by cutting off 500 cm2

Carbide band saw blades

- 75% cutting speed (m/min) and 50% feed rate (mm/min) compared to recommended values

- for smaller materials for 15 minutes

- for large materials by cutting off 500 cm2

- when vibrating, reduce the blade speed again

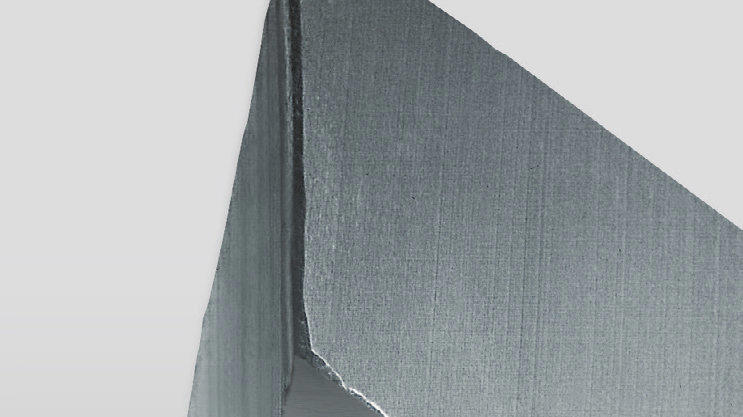

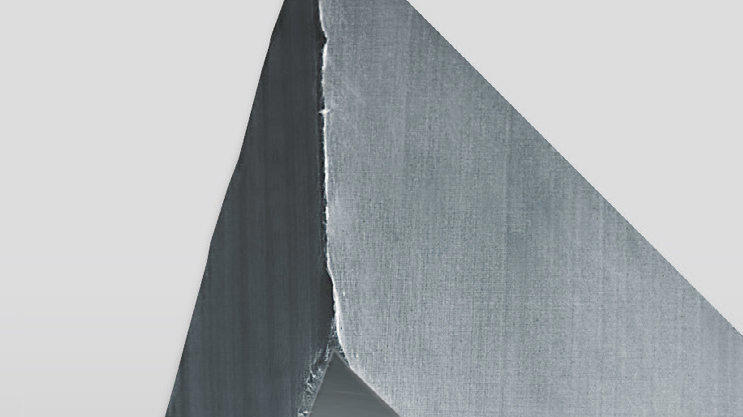

Improper run-in of band saw blades can lead to breakage of the cutting edge and thus shorten the service life

Optimal rounding of the cutting edge after correct break-in

Overloading of the cutting edge during incorrect break-in leads to breakage

The new band saw blade has a very small cutting edge radius

Information for first use

New band saw blades can be prone to vibration and noise. In this case, we recommend a further reduction of the cutting speed (m/min) until the vibrations stop.

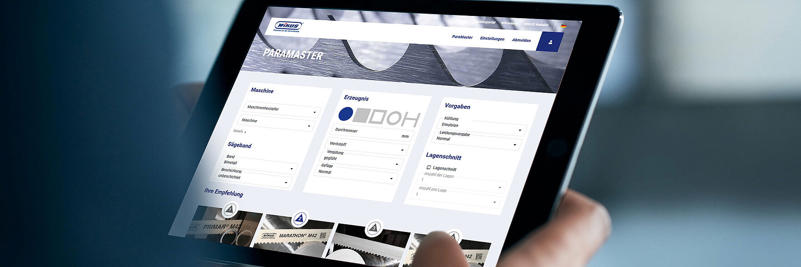

After break-in, slowly increase the cutting speed (m/min) to the recommended value and then gradually increase the feed rate (mm/min) to the values determined by our technicians, using the sliding table of cutting data or the ParaMaster program.

Other recommended steps when replacing the band saw blade:

- check the tension of the blade, which should be between 250 - 300 N/mm²

- the oil concentration in the emulsion using a hand-held refractometer and adjust if necessary

- use ParaMaster to determine optimum cutting parameters

Blade life influences

Ensuring the right operating conditions is one of the prerequisites for achieving perfect results. Optimally, the operator should check the condition of the machine and its settings step by step at each tool change.

Machine operators

Take advantage of all the ways to achieve a longer service life for your band saw blades. This brings huge savings potential, not only in simple cost per cut, but also in administrative and operational savings through less frequent replacements.

Causes of failures

Everybody encounters this at some point. The band saw blade doesn't cut or cuts badly. The type and extent of the damage can tell you a lot about the cause of the fault. The blade is just one of four possible places to look.