Common faults and possible cause

Everybody encounters this at some point. The band saw blade doesn't cut or cuts badly. The type and extent of the damage can tell you a lot about the cause of the fault. The blade is just one of four possible places to look. It's always a good idea to ask if:

- the material is of appropriate quality and properly clamped,

- the machine is regularly maintained, cleaned and adjusted,

- the operator run-in the new blade and have the correct cutting parameters,

- the band saw blade is suitably selected for the material to be cut or has no manufacturing defect.

| Possible cause | Remedy |

|---|---|

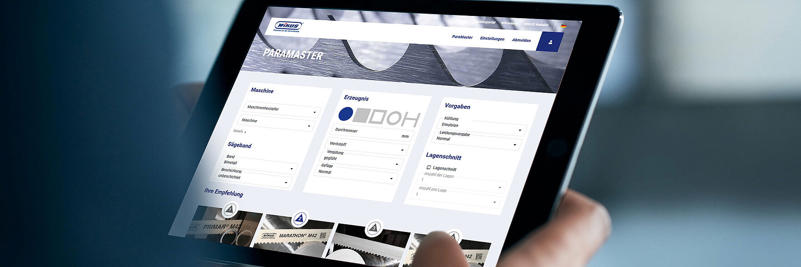

| Cutting speed too high | Reduce belt speed and check parameters with ParaMaster program |

| Insufficient cooling | Check the amount of fluid, its concentration and the routing of the inlets |

| The surface is covered with sand, scales or is extremely hard, possible inclusions in the material | Adjust cutting parameters or select a more suitable blade type, clean or sand the surface of the material at the cutting point if necessary |

| Incorrect initial use | Follow the correct run-in procedure |

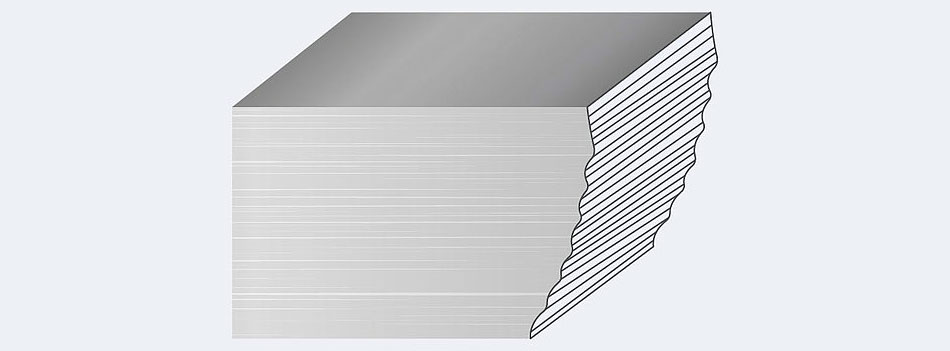

| Possible cause | Remedy |

|---|---|

| Blade speed too low | Find the correct values in ParaMaster and adjust the cutting speed |

| Too high feed into the cut | Find the correct values in ParaMaster and adjust the feed into the cut |

| Wrong tooth pitch to material dimension | Check the correct tooth pitch in our tables or choose a different geometry |

| Cut material is not sufficiently clamped | Better fix the cut material, especially for layered or bundled cuts |

| Formation of growths (built-up edges) | Check the cooling system and chip brushes |

| Hard inclusions (rock) in the material | If necessary, arrange metallographic examination of the material, a threat also for possible further machining operations |

| Possible cause | Remedy |

|---|---|

| Dulled blade | Replace the band saw blade |

| Blade guide is damaged or not adjusted | Check the guide blocks, their condition and settings |

| Side guides are set too loose | For mechanical guides set the gap to 0.02-0.05 mm, for hydraulic guides check the pressure |

| Blade guides are too far apart | Place the blade guides as close to the cut material as possible |

| Too high feed into the cut | Reduce the feed into the cut and check the parameters using ParaMaster |

| The band saw blade is not sufficiently tensioned | Check the tension of the blade using a tensometer, tighten the blade to the following values if necessary 250 - 300 N/mm2 |

| The chip brush damages the cutting edges on one side of the blade | Adjust the brush settings or replace with a new one |

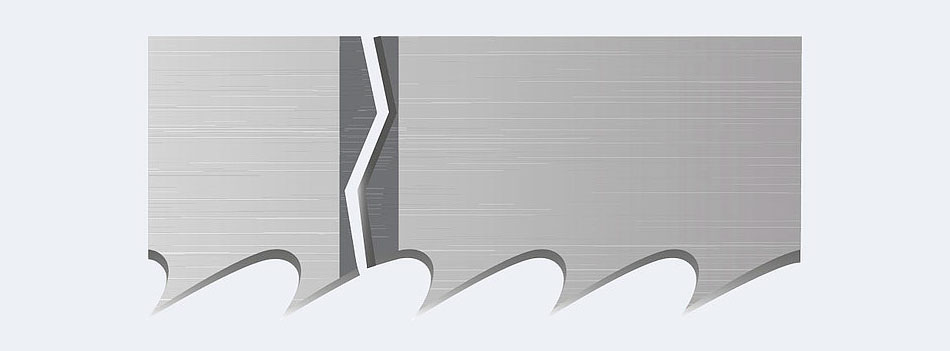

| Possible cause | Remedy |

|---|---|

| Badly welded blade | Claim the cracked band saw blade and have it re-welded, do not throw it away |

| Possible hidden machine defect | Check the machine guides and impellers |

| Possible cause | Remedy |

|---|---|

| Guide bearings are set too narrow and roll the blade | Check the bearing settings and adjust if necessary |

| The guiding elements are in the wrong position and are not aligned with the impellers | Check the settings and correct if necessary |

| The guide bearings (rollers) are jammed and wear the blade | Replace bearings |

| The guides on the sides and back of the belt are worn | Check and replace if necessary |

| The band saw blade runs too deep in the guide blocks | It must be ensured that the bases of the tooth gaps protrude 1-2 mm from the guides |

| Blade tension too high | Check the tension of the saw blade using a tensometer, tighten the blade to the following values if necessary 250 - 300 N/mm2 |

| Impellers have surface defects or a poor radius that puts uneven stress on the blade | Repair or replace impellers |

| Impellers have bad centre bearings | Adjust the clearance in the bearings or replace if worn |

| The back of the blade runs along the flange of the impellers | Adjust the position of the band saw blade (adjustment of impellers and guide) |

| Impellers are not centred | Repair or replace impellers |

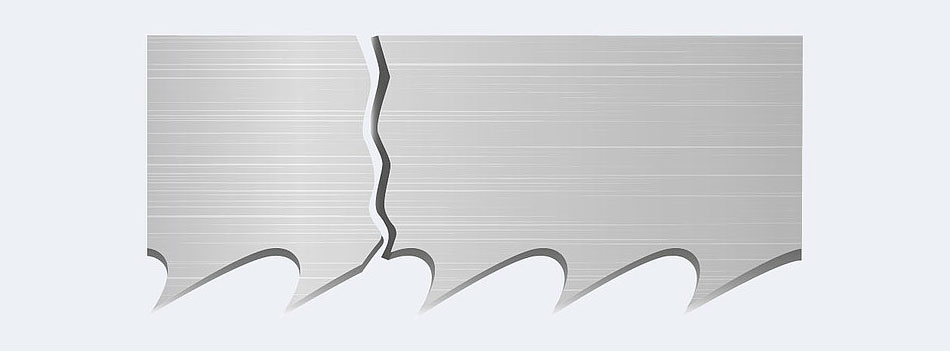

Tracking the origin of cracks can also give a clue to the cause

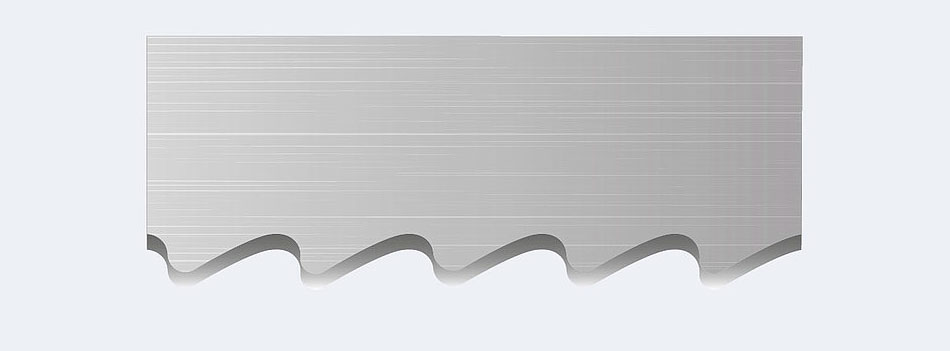

Cracking from teeth

- large tooth pitch to material size - vibrations are generated

- small tooth pitch in relation to material size - tooth gap congestion

- inappropriate cutting parameters for pitch and material

- guides set to maximum - little space to twist the blade

- the blade runs deep in the guides - contact of teeth and guiding elements

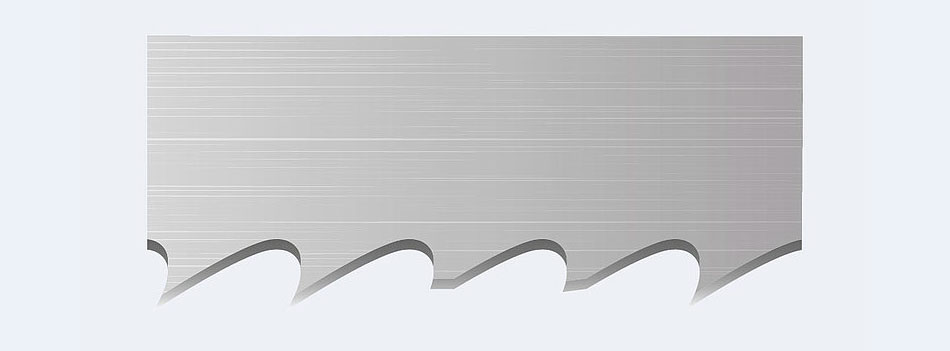

Cracking from the back

- too much feed into the cut or low speed

- worn guiding elements at the back of the blade

- the back of the blade touches the flange of the impellers

- guides too far apart

- the workpiece dimension exceeds the load capacity of the blade

- insufficient blade tension

Cracking from the middle

- worn or directly jammed bearings

- poorly aligned rollers - insufficient alignment to the guides

- damaged contact surfaces of impellers

- too large radius of the impeller surfaces

- blade too tight

Accessories

Suitable accessories are required for quality setup and adjustment. Our technicians will be happy to come and take the measurements for you, however, if you are involved in industrial cutting, we recommend that you have at least some of your own equipment for regular checks.

Refractometer

- It is used to measure the concentration of oil in the cutting emulsion and works on the principle of light refraction.

- Using a dropper, apply a sample of the emulsion to the glass and close the plastic cover to let the light hit.

- Ensure good light, focus the eyepiece and take a reading.

- Read value must be multiplied by the conversion factor.

Tachometer

- For example, it is used to measure the actual speed of the band saw blade.

- The circumference of the measuring disc is exactly 100 mm. Wear therefore affects accuracy.

- It also measures from 0.10-20.000 rpm or 0.10-1999 m/min.

- It offers measurement memory and many other settings.

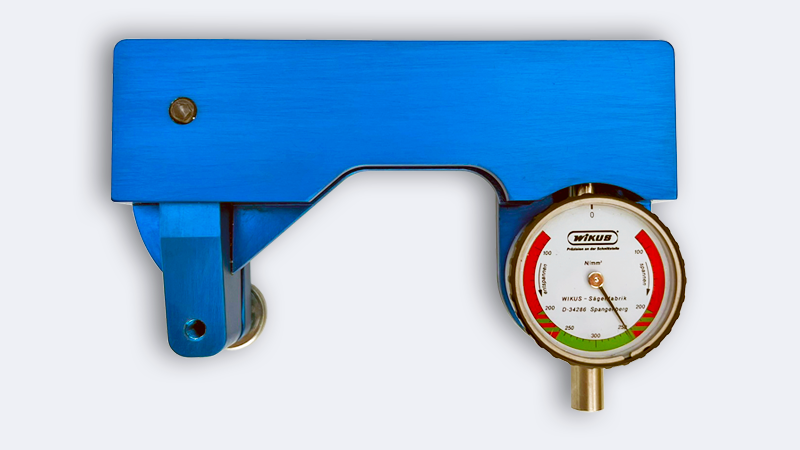

Tensometer

- It is used to measure the tension of the band saw blade on the machine.

- Automatically compensates for all deviations regardless of the dimensions of the blade.

- It can be measured during both tensioning and loosening of the blade.

- The recommended values are in the green field between 250 - 300 N/mm2.

Complete case

- It offers all the necessary equipment for measuring and adjusting machines and blades.

- Mechanical instruments: refractometer, tensometer, stopwatch, inclinometer.

- Mechanical measurements: tape measure, slide rule, stop angle, joint gauges.

- Electrical equipment: tachometer, flashlight.

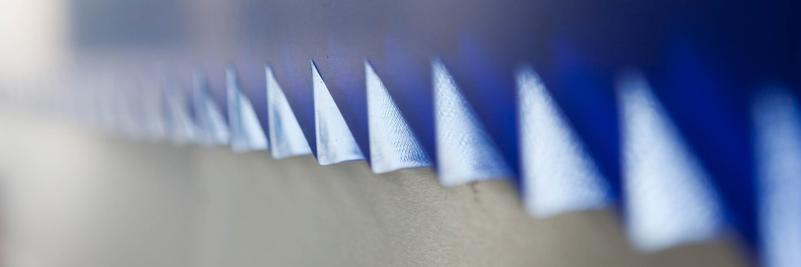

Blade life influences

Ensuring the right operating conditions is one of the prerequisites for achieving perfect results. Optimally, the operator should check the condition of the machine and its settings step by step at each tool change.

Breaking-in information

In order to achieve good performance and a long service life, the band saw blade must first be run in and the cutting edges slightly rounded. This simple but important step will ensure the reliability and efficiency of the tool.

Machine operators

Take advantage of all the ways to achieve a longer service life for your band saw blades. This brings huge savings potential, not only in simple cost per cut, but also in administrative and operational savings through less frequent replacements.