How to make the blade last longer

The operating conditions of the band saw blade significantly affect its service life. Putting on a new blade is only one of the steps an operator should take when replacing a tool. Some steps should be performed regularly at each blade change, others need only be performed at a lower frequency.

- Before removing the blade, check the distance between its back and the wheel flange, which should be 1-2 mm.

- After removal, the condition of the contact surface of the impellers and the smoothness of the centre bearings of the impellers.

- Check and clean the machine every time you change the band saw blade.

- Remove accumulated dirt around the saw frame and blade guides.

- Compressed air should be used to clean the guides.

- Check the adjustment and function of the guides, including the alignment rollers.

- Do not neglect the upper pressure guides, as a rule a glued-in carbide or bearing.

For suitable cutting parameters, we recommend contacting our technicians, using a sliding table of cutting data or the ParaMaster program.

The information needed includes:

- material designation (ISO, EN, B.S.)

- strength of material (N/mm2, HRC)

- shape of the workpiece (round, profile)

- dimensions (diameter, wall thickness)

- machine type

- customer requirement (surface quality, high performance)

This results in recommendations for the following parameters:

- type of band saw blade

- ideal tooth pitch (tpi)

- cutting speed (m/min)

- feed rate (mm/min)

- cutting performance (cm2/min)

- cutting time (min)

- oil concentration in the emulsion (%)

- performance factors for tempered materials

- Place the band saw blade with the tooth protection on the impellers and insert it into the guides.

- Tighten the saw band and check that the tension is correct - recommended values: 250 - 300 N/mm2.

- The blade tension is measured with a tensometer. If you do not have your own, our technician can take the measurement for you.

- Remove the tooth protection and allow the saw blade to run freely, adjust the chip brush.

- Check that the blade is stable. Tighten slightly after using for a while.

- Set the guides as close to the material as possible to avoid notching and cracking of the belt.

Notice:

Correct tension is extremely important for the life of the band saw blade and the accuracy of the cut. If the blade tension is too low, it will lead to an inaccurate cut and too high a tension can lead to cracks.

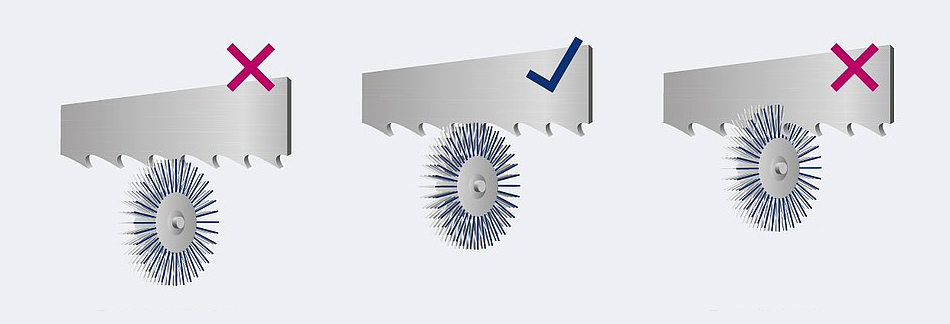

The correct setting of the chip brush ensures careful cleaning of the space between the teeth used to bring the chips out of the cut.

- If possible, the chip brush should be driven.

- Cleans the space for chips between the teeth and prevents clogging.

- Never use plastic polishing brushes or brushes without abrasive elements.

- Adjust the brush so that the tips of the fitted wires almost touch the gullet area.

- When using variable tooth pitch, adjust the brush tip to almost touch the gullet of the tooth with the lowest height.

Ensuring a sufficient supply of coolant and lubricant to the cutting point is one of the important tasks of the machine operator. The cooling system should be checked regularly in case of a blockage or drop in the tank level.

Key features include:

- reduction of friction and tool wear

- reduction of energy when shaping the chip

- frictional heat dissipation

- guarantee of a certain quality of the cutting surface

Ancillary functions include:

- chip removal

- flushing effect

- corrosion protection

In order to achieve good performance and a long service life, the band saw must first be run in and the cutting edges slightly rounded. This simple but important step will ensure the reliability and efficiency of the tool.

Notice:

As a general rule, never run a new tool into an old cut if the previous band saw blade has been destroyed.

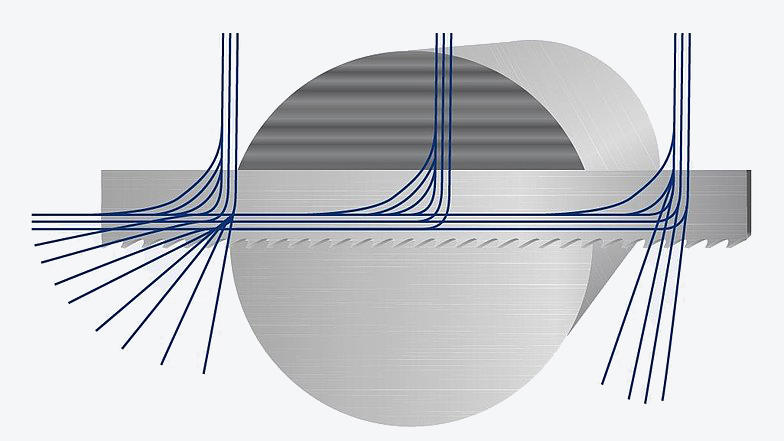

In emulsion cooling, the cutting oil and water mixture is directed onto the entire workpiece and band saw blade. In particular, it provides lubrication and cooling before and in the middle of the cut, and rinsing after the cut.

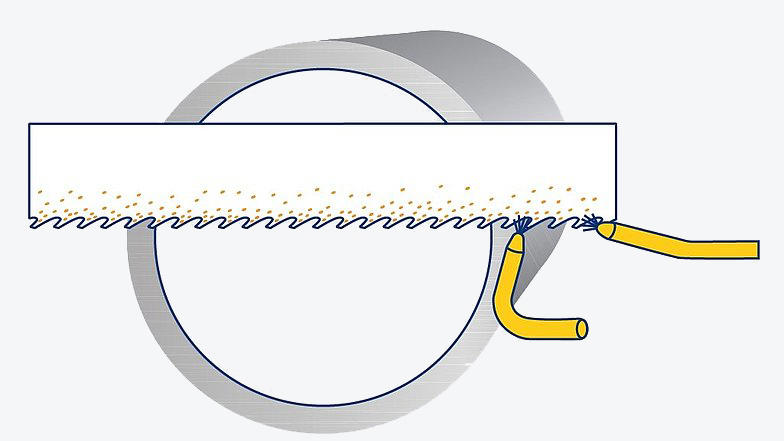

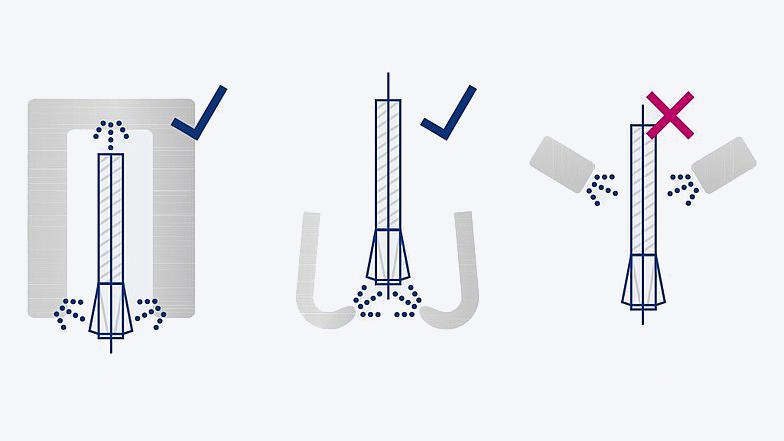

The minimum lubrication system is particularly suitable for profile cutting or special applications. Only a small amount of cutting oil is sprayed directly onto the cutting edges.

In the case of micro-lubrication, it is important to regularly check the adjust nozzle settings to ensure that the cutting edges and, if necessary, the back of the saw blade are treated correctly.

More information on lubrication

Micro-lubrication and its properties:

- applied to the teeth of the band saw blade before entering the cut

- used especially for short cutting lengths

- particularly advantageous for bundled cutting of profiles and tubes

- no need to degrease the workpiece when using a suitable lubricant

- easy retrofitting to vertical band saws

- no cooling or rinsing effect

Application:

- tubes

- profiles

- materials with special shapes

- solid materials up to Ø 250 mm (structural steel)

- solid materials up to Ø 100 mm (stainless steel)

- aluminium and aluminium alloys

Periodically check the oil concentration in the emulsion using a hand-held refractometer and the amount of medium in the tank.

The recommended concentration varies according to the material being cut in the range of 5-25% or more. For more detailed information, please contact our technician or consult the sliding table of cutting data or the ParaMaster online cutting data program from WIKUS.

Possible consequences of insufficient cooling:

- shorter life of the band saw blade body with the formation of cracks

- faster tooth wear due to higher temperatures

- sticking of the cut material to the cutting edge with subsequent breakage

Breaking-in information

In order to achieve good performance and a long service life, the band saw blade must first be run in and the cutting edges slightly rounded. This simple but important step will ensure the reliability and efficiency of the tool.

Machine operators

Take advantage of all the ways to achieve a longer service life for your band saw blades. This brings huge savings potential, not only in simple cost per cut, but also in administrative and operational savings through less frequent replacements.

Causes of failures

Everybody encounters this at some point. The band saw blade doesn't cut or cuts badly. The type and extent of the damage can tell you a lot about the cause of the fault. The blade is just one of four possible places to look.